In this article, we talk about the best diesel fuel additives for lubricity. Lubricity is how well a fuel can prevent engine parts from wearing out due to friction. These additives are important for keeping diesel engines running well. We will look at what these additives do, why they are useful, and how to choose the best one for your engine. This guide is meant to help diesel engine owners make good choices for their engines’ health and performance.

Best Diesel Additives for Lubricity Available In the Market

Here’s a list of some leading diesel fuel lubricity additives, along with their key features and measurements that make them stand out. Please note that newer products might be available, and it’s always good to check for the latest information and reviews.

| Product Name | Key Features | Measurements | Why It’s Best |

|---|---|---|---|

| 1. Opti-Lube XPD Diesel Fuel Additive | Enhances lubricity, improves cetane rating, contains anti-gel properties | Reduces HFRR score significantly | Highly rated for comprehensive benefits |

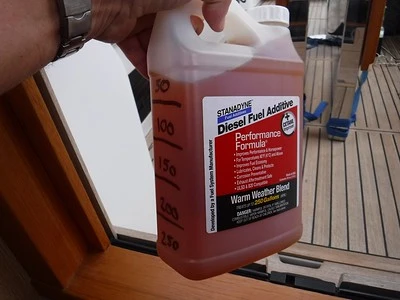

| 2. Stanadyne Performance Formula | Offers lubricity enhancement, cetane boost, cleans injectors | Reduces wear scar size in HFRR tests | Renowned for multifunctional capabilities |

| 3. Archoil AR6200 Fuel Treatment | Improves lubricity, increases cetane, enhances fuel efficiency | Claims to improve fuel efficiency | Popular for versatility and reducing emissions |

| 4. Lucas Oil Fuel Treatment | Known for cleaning and lubricating the fuel system | Concentrated formula, less quantity per gallon needed | Respected for cleaning capabilities |

| 5. Power Service Diesel Kleen + Cetane Boost | Cleans injectors, boosts cetane, enhances lubricity | Provides significant cetane increase | Favored for improving performance and efficiency |

| 6. Hot Shot’s Secret Diesel Extreme | Cleans fuel system, improves lubricity, stabilizes fuel | Effective in removing carbon deposits | Recognized for deep cleaning properties |

| 7. Schaeffer’s Diesel Treat 2000 | Enhances lubricity, reduces emissions, improves fuel economy | Designed to reduce soot and particulate emissions | Noted for environmental benefits |

Each of these additives brings unique benefits and improvements in lubricity, but it’s important to choose one that aligns with your specific engine requirements and fuel type. Always refer to the product specifications and consult with a professional if unsure about compatibility with your diesel engine.

Read related article: Is It Good To Put ATF In Diesel Fuel? (Can You Mix)

How to Choose the Right Additive for Lubricity

Choosing the right additive for diesel fuel requires careful consideration of several technical aspects and measurements. Here’s a detailed guide incorporating technical terms and measurements:

- Engine Compatibility:

- Check your engine’s specifications. Focus on the fuel system type and any manufacturer recommendations or restrictions. Modern diesel engines with high-pressure common rail (HPCR) systems may have specific additive requirements.

- Lubricity Measurement:

- Understand the High Frequency Reciprocating Rig (HFRR) value. The HFRR test measures the lubricity of diesel fuel; a lower HFRR value (measured in micrometers) indicates better lubricity. Look for additives that significantly lower the HFRR value of your diesel fuel.

- Fuel Type Compatibility:

- Ensure the additive is compatible with your specific fuel type (e.g., ultra-low sulfur diesel, biodiesel). The additive should not adversely affect the fuel’s inherent properties.

- Concentration and Dosage:

- Consider the additive concentration. High-concentration formulas are more potent, requiring smaller dosages. Check the recommended dosage, usually specified in milliliters (ml) per gallon (gal) of fuel, to ensure proper dosing.

- Chemical Composition:

- Review the chemical makeup of the additive. Look for compounds known for enhancing lubricity, such as esters, fatty acids, or polyisobutene. Avoid additives with harmful chemicals or those that might lead to deposit formation.

- OEM Approvals and Standards:

- Look for additives that meet or exceed OEM (Original Equipment Manufacturer) standards. Compliance with standards like ASTM D975 can indicate quality and suitability.

- Additional Properties:

- Some lubricity additives also offer other benefits, such as corrosion inhibitors, detergents, or cetane boosters. Assess whether these additional properties align with your engine’s needs.

- Environmental and Regulatory Compliance:

- Ensure the additive meets environmental and emission regulations. This is particularly important for commercial vehicles subject to stringent emission standards.

- Cost-Effectiveness:

- Analyze the cost per treatment and the expected benefits. Calculate the cost based on the dosage rate and the volume of the product.

After selecting and using a lubricity additive, monitor engine performance and fuel efficiency. Note changes in engine noise, responsiveness, and fuel consumption to gauge the effectiveness of the additive.

What is Lubricity By The Way?

It is the ability of a fluid, like diesel fuel, to reduce friction between surfaces in motion. It’s like how a layer of oil helps parts move smoothly against each other. In diesel engines, good lubricity in the fuel is important because it helps prevent wear and tear of engine parts. This reduces damage and extends the engine’s life. When the fuel has good lubricity, it keeps the engine running smoothly and efficiently.

Continuing from the importance of lubricity in diesel engines, it’s also key to understand how it affects performance and maintenance costs. With high lubricity, the fuel provides better protection for the engine’s internal components, like the fuel pump and injectors. These parts are critical for the engine’s operation and can be expensive to repair or replace.

When a diesel engine runs on fuel with poor lubricity, it can lead to increased friction. This friction can cause more wear on the engine parts, leading to breakdowns and a shorter engine lifespan. Additionally, engines running on low-lubricity fuel often face issues like reduced efficiency, higher fuel consumption, and even increased emissions.

Therefore, maintaining high lubricity in diesel fuel is not just about protecting the engine; it’s also about ensuring optimal performance, fuel efficiency, and compliance with emission standards. This is why choosing the right diesel fuel additive for lubricity is essential for anyone operating diesel engines.

Why Lubricity Matters

- Less Friction: Lubricity reduces the friction between moving engine parts. Think of it as oil on a door hinge; it makes things slide easier. In technical terms, it lowers the wear scar size in the High-Frequency Reciprocating Rig (HFRR) test, which means less rubbing between parts.

- Longer Engine Life: When engine parts rub against each other less, they stay in good shape for a longer time. Imagine a car engine lasting 200,000 miles instead of 100,000. Lubricity increases the engine’s lifespan, and you’ll have fewer breakdowns.

- Efficiency Boost: Smooth engine parts work better together, like a finely tuned orchestra. Lubricity enhances the engine’s efficiency by reducing friction. You’ll get more miles per gallon (MPG) from your vehicle, which means fewer trips to the gas station.

- Less Repairs: Fewer repairs mean more money in your pocket. Lubricity additives prevent engine wear, so you won’t have to replace expensive parts like fuel injectors as often. It’s like avoiding costly repairs on your car.

Benefits of Using Lubricity Additives

Using additives in diesel fuel offers significant benefits for engines, both in the short term and over the long haul. Here’s a breakdown of how these additives help and their long-term advantages:

Short-Term Benefits:

- Reduced Engine Wear and Tear: these additives create a protective layer over engine components, especially in the fuel injection system. This reduces metal-on-metal contact, diminishing wear on crucial parts like injectors and fuel pumps.

- Improved Engine Performance: By ensuring smoother operation of the fuel injection system, these additives can lead to more efficient fuel combustion. This often results in better engine responsiveness and overall performance.

- Prevention of Fuel System Failures: these additives help in keeping the fuel system in good condition. They reduce the likelihood of common issues like injector clogging or fuel pump failures, which can be costly to fix.

Long-Term Benefits:

- Extended Engine Life: Consistent use of these additives can significantly prolong the life of an engine. By reducing wear on critical components, these additives ensure that the engine runs efficiently for a longer period.

- Lower Maintenance Costs: With less wear and tear, the frequency of repairs and part replacements decreases. This leads to lower maintenance costs over the life of the engine.

- Improved Fuel Efficiency: An engine that runs smoothly and efficiently consumes less fuel. Over time, this improved fuel efficiency can lead to significant cost savings.

- Consistent Engine Performance: Regular use of additives helps maintain consistent engine performance. This is crucial for commercial vehicles and equipment where downtime or reduced performance can have a direct impact on productivity.

Lubricity additives are a small investment that can lead to substantial benefits for diesel engines. Not only do they enhance current engine performance, but they also contribute to a longer, more cost-effective service life for the engine.

Using Lubricity Additives: Best Practices

Using such additives correctly is key to maximizing their benefits for diesel engines. Here are some best practices for using these additives, along with common mistakes to avoid:

Best Practices:

- Follow Manufacturer Recommendations:

- Always read and follow the instructions provided by the additive manufacturer. This includes the correct dosage and frequency of use.

- Check if the additive is suitable for your specific type of diesel engine.

- Consistent Use:

- For the best results, use the additive regularly. Consistency is crucial in maintaining the fuel system’s health.

- Add it to the fuel tank every time you refuel, or as recommended by the product guidelines.

- Correct Dosage:

- Use the right amount of additive as per the instructions. Overdosing won’t necessarily improve performance and could be harmful.

- Underdosing may not provide the desired benefits.

- Store Additives Properly:

- Keep the additive in a cool, dry place to preserve its effectiveness.

- Make sure the container is tightly sealed when not in use.

- Monitor Engine Performance:

- Keep an eye on your engine’s performance after using additives. This helps in noticing any positive changes or detecting issues early.

Common Mistakes to Avoid:

- Mixing Different Additives:

- Avoid mixing different types of additives unless specified by the manufacturer. This can lead to chemical reactions that might reduce their effectiveness or damage the engine.

- Ignoring Compatibility:

- Not all additives are suitable for all diesel engines, especially newer models with advanced fuel systems. Ensure the additive is compatible with your engine.

- Overusing the Additive:

- Using too much additive can lead to build-up in the engine and potentially harm it. Stick to the recommended amount.

- Neglecting Regular Maintenance:

- While additives help in maintaining the engine, they do not replace regular maintenance. Continue with routine check-ups and servicing.

- Using Old or Contaminated Additives:

- Don’t use additives that have been stored for too long or have been exposed to contaminants like water or dirt.

By following these best practices and avoiding common mistakes, you can effectively use lubricity additives to enhance and protect your diesel engine, ensuring its optimal performance and longevity.

Conclusion

Choosing the best diesel fuel additive for lubricity is all about finding a product that helps your engine run smoother and last longer. The additives listed here are some of the top choices available. They can reduce wear and tear on your engine, improve its performance, and even save you money on fuel in the long run. Remember, it’s important to pick an additive that matches your engine’s needs and follow the instructions for using it. This way, you’ll get the most out of your diesel engine, keeping it running strong and efficient.