The sulfur content in diesel fuel significantly impacts both the environment and the performance of diesel engines, particularly in the context of emissions control technologies. Here’s an overview of its impact:

Environmental Effects of Sulfur in Diesel Fuel

Air Pollution and Emissions

- Sulfur Dioxide and Air Quality Deterioration: High sulfur content in diesel fuel leads to increased emissions of sulfur dioxide (SO2), a primary pollutant that significantly deteriorates air quality and contributes to respiratory problems.

- Formation of Secondary Pollutants: SO2 emissions can react in the atmosphere to form secondary pollutants like sulfate aerosols, contributing further to air quality degradation.

Contribution to Acid Rain

- Chemical Processes and Environmental Impact: The sulfur in diesel fuel, when burned, produces sulfur dioxide, which can transform into sulfuric acid in the atmosphere, leading to acid rain. This has detrimental effects on natural water bodies, soil, and vegetation.

- Effects on Ecosystems and Infrastructure: Acid rain negatively impacts ecosystems by altering the pH of soil and water, harming plant and aquatic life. It also corrodes buildings, cultural monuments, and infrastructure.

Particulate Matter Emissions

- Increased PM2.5 and PM10 Levels: Burning high-sulfur diesel fuel results in higher levels of particulate matter, specifically PM2.5 and PM10. These fine particles can travel long distances, affecting air quality over broad areas.

- Health Implications of Particulate Matter: Exposure to PM2.5 and PM10 is linked to serious health issues, including lung and heart diseases, aggravated asthma, and other respiratory problems, posing significant public health risks.

The sulfur content in diesel fuel plays a crucial role in environmental pollution, engine performance, and the effectiveness of emissions control technologies. Lowering sulfur content is essential for modern diesel engines to meet stringent emissions standards and for mitigating negative health and environmental impacts.

Read related article: What Are the Signs of Poor-Quality Diesel Fuel in an Engine?

Impact on Vehicle Performance and Maintenance

Effects on Engine Wear and Corrosion

- Accelerated Component Degradation: High sulfur content in diesel fuel can lead to accelerated wear and corrosion of engine components, such as cylinder liners and piston rings, due to the formation of acidic by-products.

- Fuel Injection System Damage: Sulfur compounds can corrode critical parts of the fuel injection system, potentially leading to injector clogging and reduced fuel spray efficiency.

Implications for Fuel Efficiency and Performance

- Reduced Combustion Efficiency: The presence of high sulfur levels can interfere with the efficient combustion of diesel fuel, potentially reducing engine performance and fuel efficiency.

- Power Output Reduction: Engines running on high-sulfur diesel may experience a decrease in power output and responsiveness due to inconsistent fuel combustion and potential deposit buildup.

Increased Maintenance Needs and Costs

- Frequent Oil Changes: Elevated sulfur levels necessitate more frequent oil changes to combat acidic build-up, leading to increased maintenance costs.

- Enhanced Wear on Emission Control Devices: High sulfur content can impair emissions control systems like Diesel Particulate Filters (DPFs) and catalytic converters, increasing the frequency of replacements or repairs.

- Overall Increased Operational Costs: The cumulative effect of accelerated component wear, reduced efficiency, and additional maintenance requirements leads to higher operational costs for vehicles using high-sulfur diesel fuel.

Read related article: Health Risks Associated with Exposure to Diesel Fuel

What effect does Sulphur have on diesel engine parts?

Sulfur in diesel fuel can have several detrimental effects on diesel engine parts, impacting both performance and longevity. Here’s an overview:

- Corrosion and Wear:

- Fuel System Corrosion: Sulfur compounds in diesel fuel can lead to corrosion in the fuel injection system and other components. This is especially problematic for high-precision parts like fuel injectors and pumps.

- Engine Wear: The acidic compounds formed from sulfur combustion can contribute to increased engine wear, particularly in the cylinder liners and piston rings.

- Lubrication Issues:

- Lubricant Degradation: Sulfur can react with the engine oil, leading to the formation of acidic by-products. These by-products can degrade the oil’s lubricating properties, reducing its effectiveness and potentially causing damage to engine components.

- Oil Change Frequency: The presence of sulfur necessitates more frequent oil changes to prevent acidic buildup and maintain engine health.

- Impact on Emissions Control Systems:

- Catalytic Converter Damage: Sulfur can poison the catalysts used in diesel oxidation catalysts (DOCs) and selective catalytic reduction (SCR) systems, reducing their effectiveness in controlling emissions.

- Diesel Particulate Filter (DPF) Clogging: Sulfur compounds can contribute to the buildup of ash and other residues in DPFs, leading to clogging and reduced filter efficiency. This can increase maintenance requirements and costs.

- Exhaust System Deterioration:

- Exhaust Corrosion: The acidic nature of sulfur combustion by-products can lead to corrosion in the exhaust system, including the exhaust manifold and exhaust pipes.

- Sensor and Component Malfunction:

- Sensor Damage: High sulfur levels can damage sensors in the engine and exhaust systems, leading to incorrect readings and potential malfunction of engine management systems.

- Reduced Component Lifespan: Continuous exposure to sulfur-related compounds can shorten the lifespan of various engine components, leading to more frequent replacements and higher maintenance costs.

Overall, the presence of sulfur in diesel fuel can cause significant challenges in engine maintenance and performance, leading to increased operational costs and the need for more frequent maintenance and part replacement. This underscores the importance of using low-sulfur or ultra-low-sulfur diesel fuels to minimize these adverse effects.

Cost Implications

- Cost Implications for Refineries and Consumers

- Refining Costs: Producing low-sulfur diesel fuel requires more complex and costly refining processes, such as hydrodesulfurization, increasing production costs for refineries.

- Consumer Fuel Prices: These increased production costs can be passed on to consumers, resulting in higher prices for low-sulfur diesel fuel at the pump.

- Operational Expenses: Vehicle owners might face higher operational expenses due to more frequent maintenance and potential engine issues caused by high-sulfur diesel.

- Impact on the Automotive Industry

- Vehicle Design and Production Costs: The automotive industry must design and manufacture vehicles compatible with low-sulfur diesel to meet emissions standards, which can increase production costs.

- Emission Control Technology Development: There is a continuous need for developing advanced emission control technologies to handle lower sulfur content, requiring significant investment in research and development.

- Market Shifts: Regions with stricter sulfur content regulations may see shifts in market preferences towards vehicles that are more efficient and environmentally friendly.

- Global Market Dynamics

- Competitiveness of Refineries: Refineries capable of producing low-sulfur diesel may have a competitive edge in markets with strict emissions standards, influencing global trade dynamics in the oil industry.

- Regulatory Impact on Trade: Differences in sulfur content regulations across countries can impact international trade, with countries adopting stricter standards potentially importing less high-sulfur diesel.

- Influence on Global Oil Prices: The global shift towards low-sulfur diesel can influence crude oil prices and demand, as the need for crude types suitable for producing low-sulfur diesel increases.

What is the problem with fuels that have high sulfur content?

- Elevated Sulfur Dioxide Emissions: Combustion of high-sulfur fuels typically results in increased emissions of sulfur dioxide (SO2), often surpassing the threshold of 15 parts per million (ppm) designated for ultra-low sulfur diesel (ULSD). This leads to heightened air pollution levels.

- Acid Rain Precursors: Sulfur compounds from these fuels react with atmospheric moisture, forming sulfuric acid, a key component of acid rain. This acidification can lower the pH of ecosystems and corrode structures made from materials like limestone and marble.

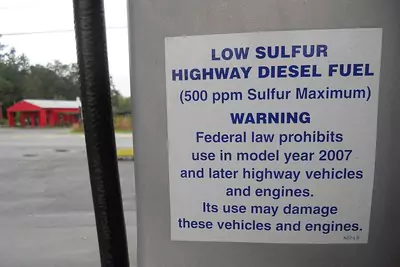

- Catalytic Converter Degradation: High sulfur levels, often above 500 ppm, can significantly impair the performance of catalytic converters and other emission control technologies like Diesel Oxidation Catalysts (DOC) and Selective Catalytic Reduction (SCR) systems, reducing their ability to control NOx and PM emissions.

- Increased Particulate Matter Emissions: The combustion of high-sulfur fuels leads to greater emissions of particulate matter (PM), specifically PM2.5 and PM10, which are known to cause respiratory and cardiovascular health issues.

- Engine Corrosion and Wear: Sulfur in fuels can promote the formation of acidic compounds during combustion, leading to increased corrosion and wear on engine components, such as cylinder liners and piston rings.

Diesel fuel needs to be low sulfur

Diesel fuel needs to be low in sulfur content for several important reasons, primarily related to environmental protection, engine health, and regulatory compliance:

- Reduction of Harmful Emissions:

- Air Pollution: Low sulfur diesel significantly reduces the amount of sulfur dioxide (SO2) and other sulfur-related emissions when burned. This is crucial in decreasing air pollution and improving air quality.

- Particulate Matter: Low sulfur content helps in reducing the formation of particulate matter (PM), particularly PM2.5 and PM10. These fine particles pose serious health risks, including respiratory and cardiovascular diseases.

- Protection of Emissions Control Systems:

- Catalytic Converters: Modern diesel engines are equipped with advanced emissions control technologies like Diesel Oxidation Catalysts (DOC) and Selective Catalytic Reduction (SCR) systems. Sulfur can poison these catalysts, reducing their efficiency and lifespan.

- Diesel Particulate Filters (DPFs): High sulfur levels can lead to clogging and reduced efficiency of DPFs, which are essential for trapping and reducing particulate emissions.

- Compliance with Environmental Regulations:

- Stringent Standards: Many countries have strict environmental regulations that require low sulfur content in diesel fuels. For instance, the Euro 6 standards in Europe and the Tier 4 standards in the U.S. mandate the use of ultra-low sulfur diesel (ULSD) with a maximum sulfur content of 15 ppm.

- Global Initiatives: Reducing sulfur content in diesel is part of global efforts to combat climate change and protect public health.

- Engine Performance and Longevity:

- Reduced Corrosion and Wear: Lower sulfur levels in diesel fuel minimize the risk of acid formation during combustion, thus reducing the corrosion and wear on engine components.

- Improved Fuel Efficiency: Engines running on low-sulfur diesel often exhibit better performance and fuel efficiency, as the fuel burns cleaner and more efficiently.

- Facilitating Cleaner Technologies:

- Technological Advancement: The shift to low-sulfur diesel fuels has spurred the development of more advanced and cleaner engine and fuel technologies.

- Hybrid and Electric Vehicles: The move towards lower sulfur content in diesel is part of a broader transition to more sustainable transportation options, including hybrid and electric vehicles.

Low-sulfur diesel is essential for reducing harmful emissions, protecting engine and emissions control systems, complying with stringent environmental regulations, improving engine performance, and paving the way for cleaner and more sustainable vehicle technologies.

Sulfur content of diesel fuel affects particulate matter emissions

- Direct Correlation with PM Emissions: The sulfur content in diesel fuel has a direct impact on the quantity and composition of particulate matter (PM) emissions. Higher sulfur levels lead to increased formation of sulfate particulates, a key component of PM.

- Influence on PM Size and Composition: Elevated sulfur levels in diesel fuel can alter the size distribution and chemical makeup of emitted particulates. This typically results in a higher proportion of fine and ultrafine particles, classified as PM2.5 and PM10.

- Aggravation of Secondary PM Formation: Sulfur compounds from diesel combustion contribute to secondary particulate matter formation. These secondary aerosols are formed when sulfur dioxide (SO2) reacts with other atmospheric compounds, leading to increased ambient PM levels.

- Impact on Diesel Particulate Filters (DPFs): High sulfur content can affect the efficiency of Diesel Particulate Filters, a critical component in modern diesel emission control systems. Sulfur compounds can lead to faster accumulation of ash and particulates in DPFs, necessitating more frequent maintenance and regeneration cycles.

- SO2 to Sulfate Conversion: In the atmosphere, sulfur dioxide emitted from diesel combustion can be converted into sulfate particles. These sulfate particles contribute significantly to the overall PM mass in the air, especially in urban areas with high diesel traffic.

Reducing the Effects of High Sulfur Content

- Advanced Refining Processes:

- Hydrodesulfurization (HDS): A process to remove sulfur, reducing diesel sulfur content to as low as 15 ppm, meeting ULSD standards.

- Alternative Techniques: Implementing newer, more efficient refining technologies for sulfur removal.

- Emissions Control Technologies:

- Diesel Oxidation Catalysts (DOCs): Converts harmful emissions, including sulfur compounds, to less harmful substances.

- Selective Catalytic Reduction (SCR): Reduces NOx emissions, more effective with low-sulfur diesel.

- Diesel Particulate Filters (DPFs): Captures particulate matter; effectiveness enhanced by low sulfur levels.

- Fuel Additives:

- Sulfur Adsorbents: Additives designed to chemically bind with sulfur, reducing its impact on engines and emissions systems.

- Engine Design Modifications:

- Corrosion-Resistant Materials: Developing engine parts resistant to sulfur-induced corrosion.

- Optimization for ULSD: Engines tailored for maximum efficiency with ultra-low sulfur diesel.

- Regulatory Measures:

- Sulfur Content Limits: Enforcing lower limits on sulfur content in diesel through legislation.

- ULSD Incentives: Tax benefits or subsidies to promote the production and use of ULSD.

- Public Awareness and Education:

- Informative Campaigns: Raising awareness about the benefits of low-sulfur diesel and the environmental impacts of sulfur emissions.

- Alternative Fuels and Technologies:

- Biodiesel and Electric Vehicles: Promoting the use of biodiesel and electric or hybrid vehicles as long-term solutions to diminish reliance on high-sulfur diesel.

Conclusion

The sulfur content in diesel fuel is a critical factor that significantly impacts environmental health, engine performance, and overall air quality. The transition to ultra-low sulfur diesel (ULSD) with sulfur content as low as 15 ppm has been a pivotal step in reducing harmful emissions such as sulfur dioxide (SO2) and particulate matter (PM), thereby mitigating air pollution and its associated health risks.

Advanced refining processes like Hydrodesulfurization (HDS) have been instrumental in achieving these lower sulfur levels. Concurrently, the development and implementation of emissions control technologies like Diesel Oxidation Catalysts (DOCs), Selective Catalytic Reduction (SCR), and Diesel Particulate Filters (DPFs) have been essential in managing the impacts of sulfur on vehicle performance and emission standards.

Regulatory measures enforcing lower sulfur limits have played a crucial role in driving these changes, demonstrating the importance of policy in steering environmental and public health initiatives. Additionally, public awareness and education, along with incentives for ULSD use, are vital for continued progress.

Looking forward, the focus on reducing sulfur content in diesel fuel aligns with broader environmental goals, including combating climate change and transitioning to more sustainable transportation modes like electric and hybrid vehicles. The issue of sulfur in diesel fuel exemplifies the intersection of technology, policy, and environmental stewardship, highlighting the ongoing challenge and importance of developing cleaner and more efficient fuel sources for the future.